- Free shipping for NZ Customers. All items are available in NZ warehouse

- +64 (0) 212576146

- [email protected]

Comparing Pressure Range Accuracy in Modern Mechanical Gauge Configurations

How Eclipse Gauges Maintain Data Stability Across Variable Engine Speeds?

May 6, 2025

Beyond the Dashboard: Why Vintage-Style Gauges Still Turn Heads in Today’s High-Tech World

June 10, 2025If you’ve worked with marine vessels long enough, you already know that pressure monitoring is a game of precision. Whether it’s oil pressure, fuel, or air, even minor fluctuations can affect performance or signal an issue waiting to escalate.

For marine professionals, especially across the diverse waters of New Zealand, Mechanical Gauges remain a go-to solution thanks to their simplicity, durability, and reliability.

But here’s the key question—how accurate are they across different pressure ranges?

In this article, we break down how various mechanical gauge configurations perform when it comes to pressure accuracy, what factors impact that accuracy, and how to choose the right range and setup for your vessel's operational needs.

Why Pressure Accuracy Still Starts with Mechanical Gauges?

Even in a world moving toward digital dashboards, Mechanical Gauges still have the edge when it comes to raw durability and reliability—especially in tough marine environments. They don’t rely on electricity, they don’t glitch under signal interference, and most importantly, they offer a direct, real-time readout that’s trusted by engineers, skippers, and mechanics alike.

But the challenge isn’t just about “having” a gauge—it’s about choosing the right pressure range and configuration so that you get readings that matter.

How Pressure Range Affects Accuracy?

Understanding Pressure Range vs. Resolution

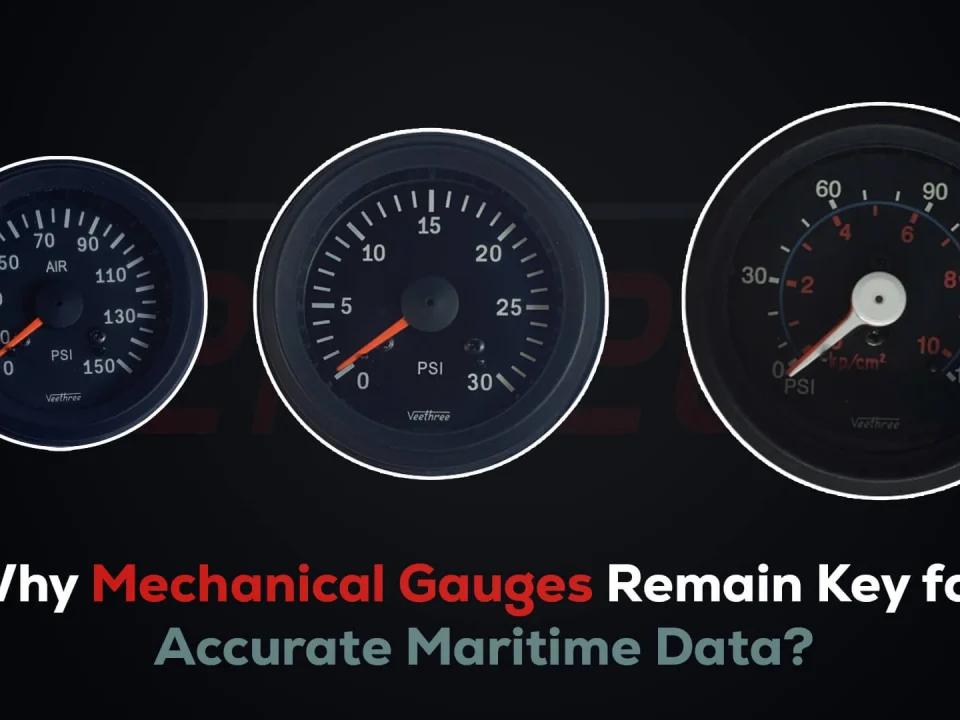

Most mechanical pressure gauges come in standard pressure ranges (e.g., 0–30 PSI, 0–100 PSI, 0–300 PSI). While it might seem like “bigger is better,” that’s not always true.

A 0–300 PSI gauge might technically cover your system’s peak pressure—but if your system typically operates around 40–60 PSI, that gauge will deliver less accuracy at that normal operating level.

Why It Matters: A gauge performs best when your average pressure falls in the middle third of its range. That’s where resolution and needle stability are optimal.

Low-Pressure vs. High-Pressure Configurations

Low-pressure gauges (e.g., 0–30 PSI) are often used for applications like fuel systems or air pressure where precision is key at smaller values. These gauges generally have finer graduations and offer more readable sensitivity in the lower range.

On the other hand, high-pressure gauges (e.g., 0–300 PSI) are built to handle systems like oil pressure or hydraulic lines where spikes are possible. But they often come with wider scale spacing, which can reduce resolution at the lower end.

Key Insight: Choose your pressure range so that the system’s normal operating pressure sits between 30% and 70% of the full scale. This gives the best balance between accuracy and safety margin.

The Mechanics Behind Gauge Accuracy

Let’s take a quick look under the hood—literally.

Bourdon Tube Construction

Most marine-grade mechanical gauges, including those from Veethree, use a Bourdon tube mechanism. As pressure enters the tube, it flexes slightly, and this movement is translated through gears to the needle on the dial.

The shape, material, and tension of that tube determine the gauge’s sensitivity and accuracy. In lower-range configurations, tubes are thinner and more flexible, allowing more responsive movement.

In high-pressure versions, they’re thicker and more robust—better for durability, but with slightly slower response.

Why It Matters: The physical build of the gauge changes depending on its rated pressure, and that has a direct impact on how finely it can display small pressure changes.

Needle Travel and Dial Layout

Dial design matters too. In mechanical gauges, the distance the needle travels across the dial is fixed. The fewer the total PSI, the more spaced out each unit on the dial will be. This makes it easier to read small changes.

For example: A 2" dial with a 0–30 PSI scale might show each PSI as a noticeable movement.

The same dial with a 0–300 PSI scale would require 10 PSI before you see significant needle movement.

Designed for the Demands of New Zealand Marine Conditions

In New Zealand, vessels often face sudden pressure changes due to tidal currents, wind shifts, or system load variations. Whether it’s a fishing vessel operating hydraulic winches or a launch cruising at variable RPMs, Marine Gauges must offer both ruggedness and accuracy.

Veethree mechanical gauge configurations are designed to hold calibration across varying pressure environments, high vibration, and exposure to salt air—key for professionals operating around the Hauraki Gulf, Cook Strait, or the deep south.

Choosing the Right Mechanical Gauge Configuration

Now that we understand how pressure range affects accuracy, let’s talk about selecting the right configuration for your system.

Match the Gauge to Your Normal Operating Pressure

A common mistake is buying a gauge based on the system’s maximum possible pressure instead of its normal working range. For example, if your system occasionally spikes to 100 PSI but typically runs at 40 PSI, a 0–100 PSI gauge is better than a 0–300 PSI option. You’ll get more needle movement in the area that matters most.

Pro Tip: Pick a gauge where the normal pressure sits at around 50%–60% of the full scale. That’s where accuracy is typically highest.

Consider Dial Size for Visibility

Smaller dials are great for tight panels, but if you're checking the gauge at a distance—or in low light—consider upsizing to a 2.5" or 3" face for better clarity.

Why It Matters: Visibility plays a role in how quickly you can spot an abnormal reading—critical when pressure is fluctuating under load.

Use Liquid-Filled Gauges in High-Vibration Settings

For engine rooms or vibration-prone areas, liquid-filled mechanical gauges offer additional stability. The internal fill fluid dampens needle bounce, making readings easier to interpret when the vessel is in motion.

In Marine Applications: This is especially useful for fuel or oil pressure gauges installed near the engine.

Installation Tips That Preserve Accuracy

Even the most accurate gauge can be thrown off by poor installation. Here’s how to avoid that.

Mount the Gauge Upright and Steady

Always install gauges in a position that keeps the internal mechanism neutral. If the gauge is tilted, gravity may interfere with the movement, especially at lower pressures.

Pro Tip: Use marine-rated panel mounts or vibration-dampening brackets.

Avoid Direct Engine Heat

Heat affects pressure readings by causing thermal expansion within the gauge’s internal parts. Always install gauges at a safe distance from hot surfaces or use thermal shielding when necessary.

Check Fittings for Air or Oil Leaks

Leaks not only reduce system pressure but can introduce air bubbles or contaminants into the Bourdon tube—affecting the needle's response.

Best Practice:

Use PTFE tape or thread sealant approved for your specific system type, and perform a leak test after installation.

Long-Term Accuracy and Maintenance

Periodic Calibration ChecksMechanical Gauges typically hold calibration well, but over time, especially in marine conditions, it’s smart to schedule yearly calibration checks. Some vessels do this as part of their annual haul-out service.

Clean the Dial Face RegularlySalt mist and condensation can obscure your view. Use a soft cloth and fresh water—never harsh cleaners that could degrade the seal or lens.

Replace Before FailureIf the needle starts to stick, bounce abnormally, or fails to return to zero, replace the gauge. Mechanical failure is rare but should be treated as a serious warning sign.

Our Verdict

In the world of Marine Gauges, pressure range accuracy isn’t just a technical specification—it’s a safety factor. By choosing the right Mechanical Gauge configuration aligning it with your system’s normal pressure range, and maintaining it properly, you ensure that you’re getting the most reliable feedback possible.

Mechanical gauges by Veethree are built for real-world marine conditions—designed to resist corrosion, vibration, and thermal distortion—while still delivering the kind of needle stability and clarity that professionals depend on.

In short? These gauges keep you informed when it matters most, with data you can trust—no batteries, no lag, just precision built to perform.

FAQs